Custom Glass Fabrication Specialties

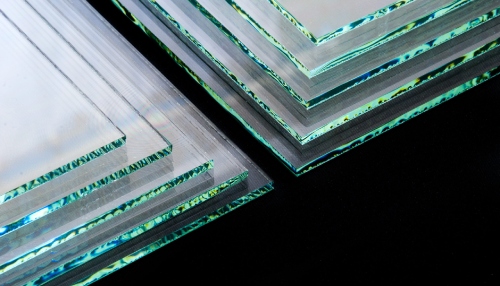

Specializing in precision fabrication with thicknesses from 0.1mm to 16 mm,

our advanced glass fabrication capabilities can cut and machine glass to tolerances of ±.002".

CNC Machining CNC machining processes enable us to produce highly detailed glass components with excellent precision and speed.

CNC Scribing We leverage CNC technology in our S & B services for optimal component separation at high speeds and low risk of chipping.

Machine Edging Our glass edging machines grind and polish the edge of glass substrates while maintaining close tolerances and reducing processing times.

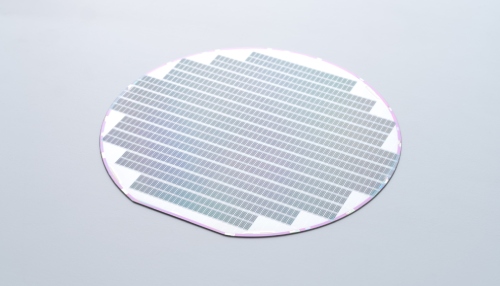

Precision Dicing Using state-of-the-art dicing equipment, we realize our clients’ designs with high-precision wafer dicing and scribing techniques.

Lapping & Polishing Our lapping and polishing techniques use abrasives to reduce the thickness and improve the surface of glass substrates.

Metrology We provide quality assurance for sophisticated components by leveraging state of the art optical comparators and laser micrometers.

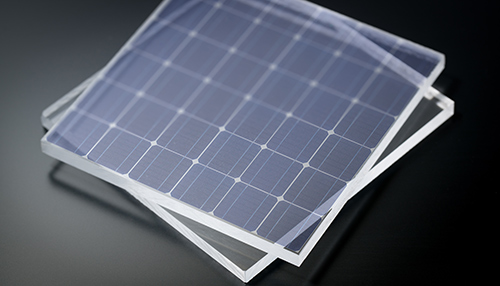

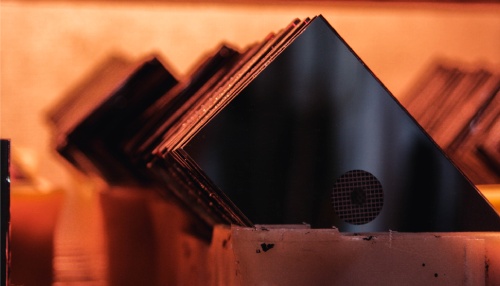

Our Glass Materials Catalog

We offer a diverse selection of quality glass materials competitively priced to meet your standards within the scope of your project.

Our History

Established as S. I. Howard Plate Co in 1912, we became incorporated as S. I. Howard Glass Co., Inc. in 1948. Since then, we have been producing quality, flat glass products to the instrument makers of the world.

Industries Served

Since our small beginnings, we now proudly serve our dedicated customers operating within a variety of industries.