Overview of the CNC Milling Process

CNC milling is a subtractive manufacturing process; it uses multi-point rotary cutting tools to remove material from a workpiece to achieve the desired shape and size. It begins with the creation of a computer-aided design (CAD) drawing or 3D model of the component. The dimensional data from the drawing/model is then exported into a compatible file format and converted into instructions for the computer-aided manufacturing (CAM) software. The instructions direct the movement and action of the CNC milling machine and the machine tools, ensuring material is removed from the workpiece along the proper axes and paths.

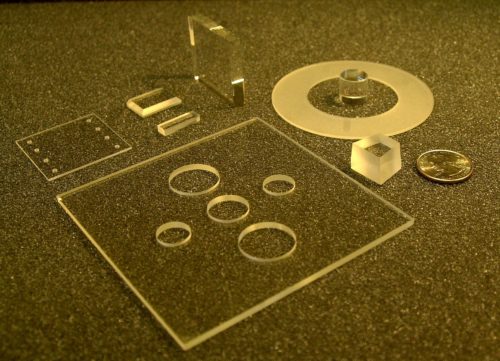

The CNC milling process can be employed to manufacture a variety of glass parts and products, ranging in size, shape, and complexity. The particular type of CNC milling technique utilized depends on the component design. Some of the most common are:

- Plain milling: This technique uses cutting tools that rotate on an axis parallel to the surface of the workpiece to remove material.

- Face milling: This technique uses cutting tools that rotate on an axis perpendicular to the surface of the workpiece to remove material.

- Angular milling: This technique uses cutting tools that rotate on an axis at an angle to the surface of the workpiece to remove material and create angular cuts.

- Form milling: This technique uses specific cutting tools to form non-flat cuts (e.g., contours, curves, and radii).