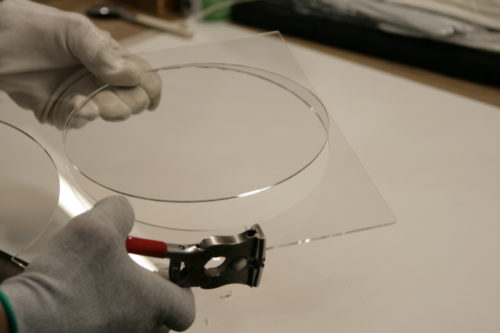

S.I. Howard Glass Company is an ISO 9001-certified and ITAR-registered supplier of glass parts and products. In addition to maintaining a wide range of quality standard glass products, we offer a broad selection of custom glass fabrication capabilities. One of our core service offerings is CNC scribing, a manufacturing process used to form partial cuts that facilitate the separation of individual components from the workpiece material.

Overview of the Scribe and Break Process

Scribe and break (S & B) is a separation technique that relies on the physical properties of the workpiece material. It uses a dry cutting process, which helps improve processing speed compared to other separation techniques. Additionally, it requires extremely small processing widths (scribe lines are typically only a few micrometers), which allows for more components to be made from a single workpiece.

The process steps are as follows:

- Scribing: forming partial cuts through the substrate

- Breaking: cracking the substrate along the formed cuts to separate the component

The process can create components at high speeds with a low risk of chipping when performed properly.