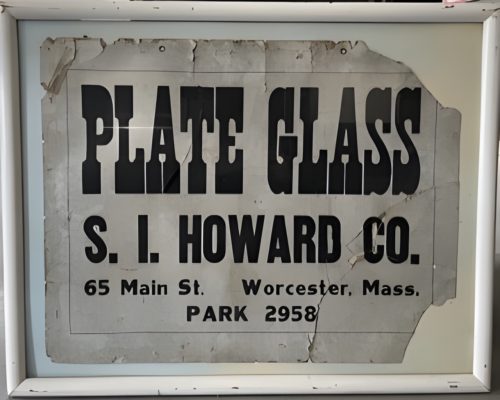

At first, Howard Glass was known for quality glazing and store front installations. After WWII, when Mr. Farmer returned home from serving in the war, he noticed a shift in the market as a demand for glass parts for instruments emerged. He acquired customers such as Geier & Bluhm (still our customer to this day) Stocker & Yale, and Mason & Sullivan. S. I. Howard Glass Co., which became incorporated in 1948, began making parts for clocks, military compasses, and other tools. By the mid 1970s, we no longer served residential and commercial properties, but were solely focused on the instrument makers of the world.

Today, our base of over 500 customers ranges from optics to biomedical, electronics to aerospace, and prototyping for research and development. We specialize in edge grinding, grinding and polishing, CNC machining, dicing, scribe and break and heat strengthening. We carry over $1 million in inventory in a broad range of glass types for optical and industry. As of 2015, we are both ISO certified and ITAR registered. We could not be more proud of history, our products, our customers, and especially of the employees who brought us to where we are today.

Our Fabrication Specialties include:

- SCRIBE AND BREAK

- GRINDING AND POLISHING

- MACHINE EDGING

- PROTOTYPING

- PRECISION DICING

- CNC MACHINING

- HIGH VACUUM COATINGS

- DRILLING

- LAMINATING

- HEAT STRENGTHENING

- SANDBLASTING AND FROSTING

Our pricing is very competitive. Prices are listed on this website for all of our glass types by square foot. Please do not hesitate to contact quotes@howardglass.com for pricing on a customized part.